Heat Exchanger Tubes and Seamless Tubes | Stainless Steel 304, 316, 317L, 904L Grades | ASTM & ASME Standards

In industries such as oil and gas, chemical processing, power generation, pharmaceuticals, and food production, the demand for high-performance tubing solutions continues to rise. Two of the most critical types used across these sectors are Heat Exchanger Tubes and Seamless Tubes. Both play essential roles in maintaining temperature control, fluid transport, and overall system integrity under extreme conditions.

This blog provides a detailed understanding of Heat Exchanger Tubes and Seamless Tubes, focusing on the most commonly used stainless steel grades — 304, 304L, 316, 316L, 317/317L, and 904L — along with their respective international standards like UNS, DIN, JIS, BS, EN, ASTM, and ASME SA.

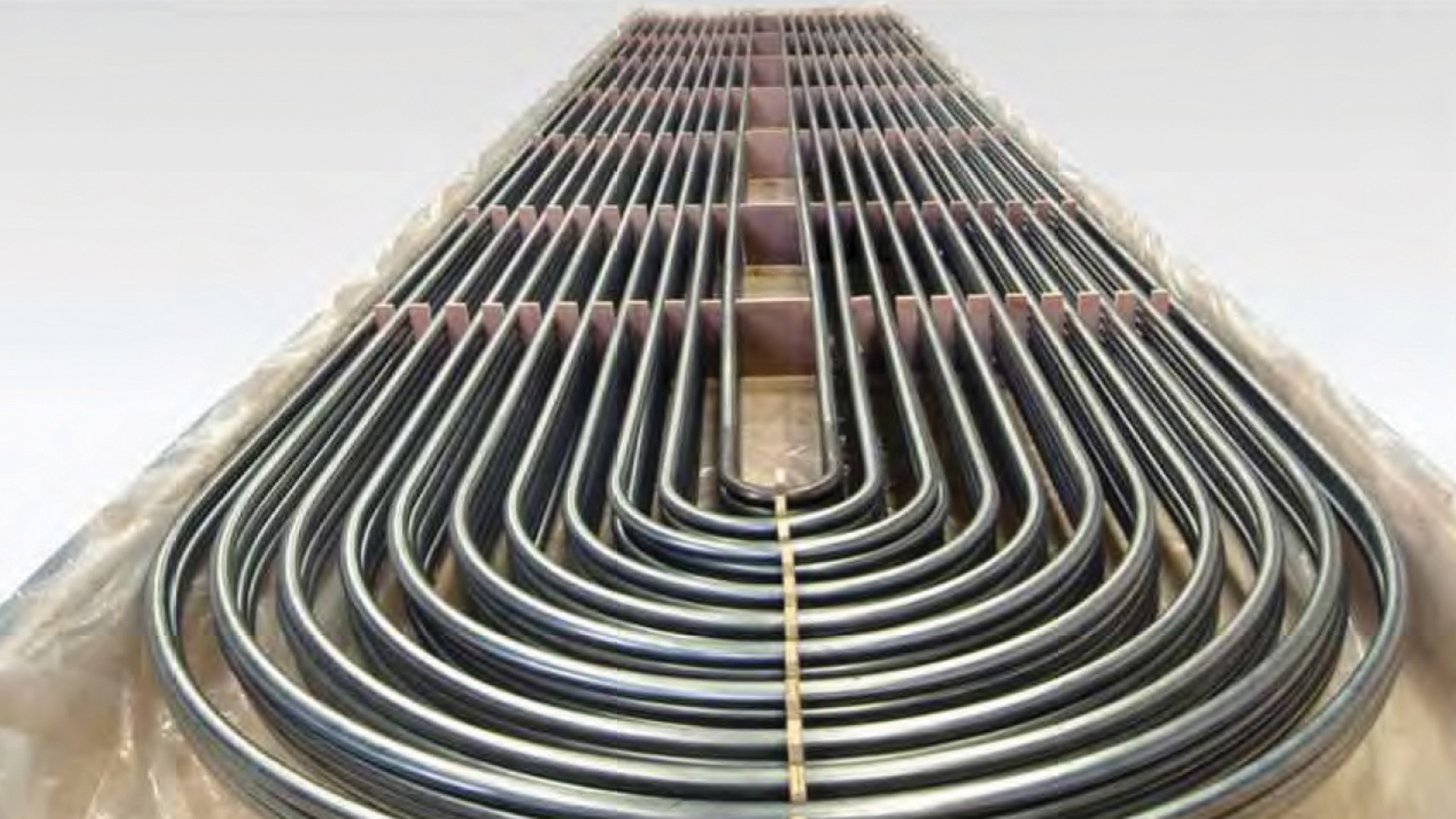

What Are Heat Exchanger Tubes?

Heat Exchanger Tubes are designed to efficiently transfer heat between two or more fluids while keeping them physically separated. These tubes are used in condensers, boilers, evaporators, coolers, and heat recovery systems. The choice of material for these tubes is crucial because they must withstand high temperature, pressure, and corrosive environments without degrading over time.

Stainless steel is one of the most preferred materials for heat exchanger tubes due to its corrosion resistance, mechanical strength, and long service life. Different grades of stainless steel are chosen based on the operating conditions and the nature of fluids being processed.

Types of Stainless Steel Used in Heat Exchanger Tubes

Below are the most widely used grades for Heat Exchanger Tubes, each offering unique characteristics suited for specific environments.

Stainless Steel 304 Heat Exchanger Tubes (UNS S30400 / DIN 1.4301 / JIS SUS 304)

Stainless Steel 304 Heat Exchanger Tubes are among the most common choices due to their excellent corrosion resistance, formability, and weldability. Manufactured according to ASTM A213 / A249 / ASME SA213 / SA249, these tubes perform reliably in moderate temperature and non-corrosive environments.

They are widely used in food processing, beverage industries, and HVAC systems. The presence of chromium and nickel enhances their oxidation resistance, making them ideal for applications where hygiene and temperature consistency are essential.

Stainless Steel 304L Heat Exchanger Tubes (UNS S30403 / DIN 1.4306 / JIS SUS 304L)

The Stainless Steel 304L Heat Exchanger Tubes are a low-carbon version of 304, designed to minimize carbide precipitation during welding. They comply with ASTM A213 / A249 / ASME SA213 / SA249, and are preferred in welded heat exchangers and condensers.

Because of their lower carbon content, 304L tubes offer enhanced resistance to intergranular corrosion, making them ideal for chemical and pharmaceutical industries where purity and corrosion resistance are crucial.

Stainless Steel 316 Heat Exchanger Tubes (UNS S31600 / DIN 1.4401 / JIS SUS 316)

Stainless Steel 316 Heat Exchanger Tubes are known for their superior resistance to chlorides and acidic environments, due to the presence of molybdenum. These tubes conform to ASTM A213 / A249 / ASME SA213 / SA249 / EN 10216-5, ensuring consistency and performance.

They are used in marine applications, desalination plants, and offshore industries where exposure to saltwater and harsh chemicals is common. The enhanced corrosion resistance of 316 tubes increases the lifespan of the heat exchanger system.

Stainless Steel 316L Heat Exchanger Tubes (UNS S31603 / DIN 1.4404 / JIS SUS 316L)

For applications requiring both excellent corrosion resistance and weldability, Stainless Steel 316L Heat Exchanger Tubes are the preferred choice. Manufactured under ASTM A213 / ASME SA213, they resist intergranular corrosion even after welding.

These tubes are extensively used in chemical processing, pharmaceuticals, and food industries, where they maintain mechanical integrity even under continuous exposure to acids and alkalis. The 316L grade ensures long-term reliability in critical systems.

Stainless Steel 317/317L Heat Exchanger Tubes

Stainless Steel 317 and 317L Heat Exchanger Tubes are high-alloy variants designed for environments with severe corrosion risks. They conform to ASTM A213 / A249 / ASME SA213 / SA249, offering excellent resistance to pitting and crevice corrosion.

Used in chemical and petrochemical industries, these tubes withstand exposure to sulfuric and hydrochloric acids. The higher molybdenum and nickel content improves strength and ensures performance even in reducing atmospheres.

Stainless Steel 904L Heat Exchanger Tubes

Stainless Steel 904L Heat Exchanger Tubes belong to the super austenitic category and are designed for extreme corrosive environments. They adhere to ASTM A213 / ASME SA213 / EN 10216-5, offering unmatched resistance to sulfuric, phosphoric, and acetic acids.

These tubes are commonly used in fertilizer plants, pulp and paper industries, and pollution control equipment. With high nickel and molybdenum content, 904L delivers exceptional performance in environments where standard stainless steels fail.

What Are Stainless Steel Seamless Tubes?

Seamless Tubes are manufactured from solid billets that are pierced and elongated without any welding or joints. This process ensures a uniform grain structure, high strength, and superior pressure resistance.

Stainless Steel Seamless Tubes are produced according to international standards like ASTM A312 / A213 / ASME SA312 / SA213 / EN 10216-5 / DIN 17456, making them ideal for high-pressure and high-temperature applications.

Conclusion

Both Heat Exchanger Tubes and Seamless Tubes play pivotal roles in industrial operations. Choosing the right stainless steel grade—304, 304L, 316, 316L, 317/317L, or 904L—ensures optimal performance, durability, and compliance with international standards.

Stainless Steel Seamless Tubes

Stainless Steel Seamless Tubes