Stainless Steel 317/317L Boiler Tubes vs Stainless Steel 304 Boiler Tubes

Stainless steel boiler tubes are pivotal components in the manufacturing and industrial sectors, known for their durability and resistance to corrosion. Among the various types of stainless steel available, Stainless Steel 317/317L and Stainless Steel 304 are popular choices for boiler tube applications. While both offer excellent performance, they possess distinct characteristics that make them suitable for specific conditions. In this article, we will compare Stainless Steel 317/317L boiler tubes with Stainless Steel 304 boiler tubes, highlighting their differences in composition, properties, and applications to help you make an informed decision for your boiler system.

Overview of Stainless Steel 317/317L Boiler Tubes

Stainless Steel 317/317L boiler tubes are known for their high creep and stress rupture properties, making them ideal for high-temperature applications in boiler systems. With a higher molybdenum content compared to Stainless Steel 304, these tubes offer enhanced corrosion resistance, particularly in harsh chemical environments.

The dual-phase microstructure of Stainless Steel 317L provides excellent toughness and improved weldability, ensuring longevity and reliability in demanding boiler operations. Stay tuned as we delve deeper into the specific characteristics and advantages of Stainless Steel 317/317L boiler tubes in the next section.

Overview of Stainless Steel 304 Boiler Tubes

Stainless Steel 304 boiler tubes are renowned for their versatility and durability in various boiler applications. While not as resistant to high temperatures and harsh chemicals as Stainless Steel 317/317L, Stainless Steel 304 tubes excel in moderate temperature environments and are cost-effective solutions for many industries.

Their excellent corrosion resistance, ease of fabrication, and low maintenance requirements make them a popular choice for a wide range of boiler systems. In the upcoming section, we will explore the specific features and benefits that Stainless Steel 304 boiler tubes offer in comparison to Stainless Steel 317/317L tubes.

Key Comparisons: Performance, Durability, and Corrosion Resistance

When it comes to choosing between Stainless Steel 317/317L and Stainless Steel 304 boiler tubes, performance, durability, and corrosion resistance are critical factors to consider. Stainless Steel 317/317L boasts higher resistance to extreme temperatures and harsh chemicals, making them ideal for demanding boiler applications.

On the other hand, Stainless Steel 304 tubes are cost-effective and perform exceptionally well in moderate temperature environments. Understanding the specific needs of your boiler system is essential in selecting the right material that aligns with your performance requirements and budget.

Benefits of Using Stainless Steel 317/317L Boiler Tubes in High-Temperature Applications

Stainless Steel 317/317L boiler tubes offer outstanding benefits when utilized in high-temperature applications. Their superior resistance to extreme heat, coupled with excellent corrosion resistance properties, ensures reliable performance and longevity in demanding boiler systems.

The high molybdenum content in Stainless Steel 317/317L enhances their resistance to pitting and crevice corrosion in aggressive environments, making them a preferred choice for industries requiring exceptional durability under harsh conditions.

Cost Considerations: Stainless Steel 317/317L vs. Stainless Steel 304

When evaluating boiler tube options, cost is a crucial factor to consider. While Stainless Steel 317/317L boiler tubes offer exceptional performance in high-temperature environments, they generally come at a higher price point compared to Stainless Steel 304 tubes.

The superior corrosion resistance and high molybdenum content in Stainless Steel 317/317L contribute to its elevated cost. In contrast, Stainless Steel 304 boiler tubes present a more cost-effective alternative for applications where extreme temperature and corrosion resistance are not primary concerns.

Conclusion

Choosing the right boiler tube for your specific needs requires a thorough evaluation of performance requirements, cost considerations, and environmental conditions. While Stainless Steel 317/317L boiler tubes offer unparalleled performance in high-temperature and corrosive environments, they do come at a higher price point compared to Stainless Steel 304 tubes.

By assessing your boiler system's unique requirements and consulting with industry experts, you can make an informed decision that ensures optimal performance and cost-efficiency in the long run.

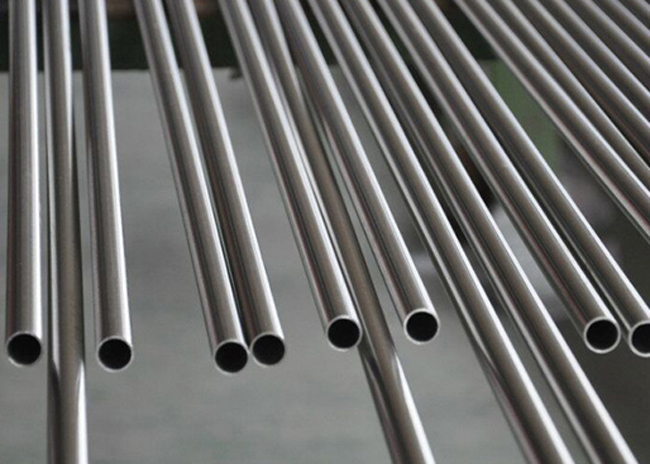

Stainless Steel Seamless Tubes

Stainless Steel Seamless Tubes